Fire Safety and Industrial Roof Systems

Industrial roof fires may not always attract the same attention-grabbing headlines as those affecting domestic buildings, but the consequences can be just as devastating and far reaching. At worst, an industrial roof fire has the potential to collapse an entire building, which means roof fire safety should be of top concern to your clients.

Whether you’re working on behalf of a landlord or tenant, buyer or seller, you’ll already be aware of fire safety when it comes to roof inspections or repairs. Nowadays, everyone’s looking to trim costs wherever possible, but it’s important that your client does not evade safety issues, and this includes choosing suitable materials for roof repairs.

What impacts roof fire safety?

Government figures show there were over 4,200 fires in England between 2018 and 2020, where the roof was considered to play a primary role in growth and spread. According to fire service reports, around half of all roof fires are the result of arson.

Hot works are another cause, whether from welding, grinding or other applications of heat, including torch-applied roofing materials. Solar panels and air-conditioning units can be fire hazards too, with electrical arcing being a particular area of concern.

But fire can also spread from elsewhere within industrial buildings with devastating consequences, particularly where a roof or its coatings are made from combustible materials. Faulty electrical wiring is a common cause of fires for commercial premises.

Raising the issue

Fire safety measures tend to focus on compartmentalising areas of a building, but particularly in the case of older industrial buildings, the roof could be overlooked. Many business owners and managers might not consider the implications of roof fire safety, so it’s worthwhile bringing this to their attention.

You might choose to highlight the 2019 fire which destroyed a state-of-the-art Ocado warehouse, resulting in 400 redundancies and costs of well over £100m. Although there were several factors that influenced the progress of the fire, once it had got into the roof it inevitably resulted in total collapse.

Even where the full collapse of a building is avoided, the costs of repair can be crippling. And with numerous industrial roof fires reported every year, there’s clearly room for improvement.

Roof fire safety and the law

The laws concerning fire standards for flat roofs are not clearly defined, although there are increasing calls for the roof to be treated as a ‘fifth wall’. There are many popular terms that imply a degree of protection from fire but may lack meaning in legal terms, such as ‘Fireproof’, ‘fire retardant’, ‘fire safe’ and ‘Class 0’.

Until recently the Building Regulations and Approved Document B had focussed attention primarily on walls, and although some changes have now been introduced there is a general belief that the regulations should go even further. For example, although the external spread of fire is dealt with in part B4 of the Building Regulations, there is no outright ban on the use of combustible material in flat roofs or insulation.

Approved Document B of the Building Regulations is concerned with the evaluation of a roof’s performance when subjected to extreme heat. The highest achievable level is BROOF(T4), but this still fails to take into account the way in which individual components will react to fire. Neither does it indicate how well the roof might perform if exposed to fire from elsewhere in the building, including the implications of smoke production and the emission of toxic gases.

One practical way of getting around this is to check roofing materials for their Euroclass rating, regarding its reaction to exposure by fire. Non-combustible materials will have a rating of either A1 or A2-s3,d2. It’s worth noting that roofing products containing materials with a Euroclass rating as low F can still achieve the highest performance level of BROOF(T4).

This shows that even BROOF(T4) is not sufficient to ensure compliance with the current regulations. And since they specify that any roofing materials over compartment walls must be on a deck or substrate of A2-s3,d2 material at the very least, it’s essential to ensure this is done. One way forward is to advise your clients to get a Declaration of Performance (DoP) certificate from roofing product manufacturers.

When it comes to fire safety, we would recommend advising your clients to check their roofing products and materials do not hinder the legal fire classification of a roof.

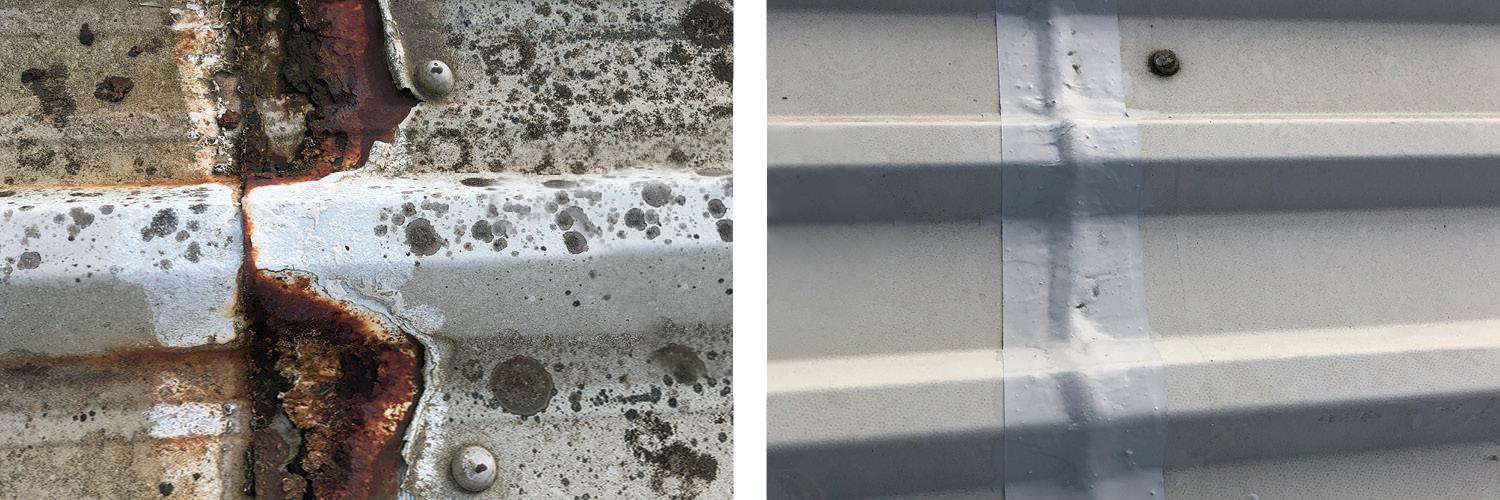

Once applied and fully dry, Giromax® coating products are a fire-safe option for industrial roofing systems. BBA Approved and guaranteed for up to 20 years, our range of market-leading coatings are a high-performance choice for a variety of roof and guttering repairs.

Get updates from us

Sign up to our newsletter to receive all the latest news and insights from Giromax Technology.

Subscribe to NewsletterRelated articles

The Lifecycle of a Coated Roof

What is the typical lifecycle of a coated roof? Depending on the substrate, structure and the type of coating, the...

The History of Cladding: Metal Roofing

Modern metal roofing has become a familiar sight in this country, thanks to its strength, durability, weather resistance and ability...

Giromax Cut Edge Corrosion Treatment

The Giromax team explains the design criteria governing the development of Cut Edge Corrosion treatment on Profiled Steel roofing.